Focus

Focus

Equipment for biological air treatment

Airborne contamination has always been a serious problem in our society; in fact there are many airborne diseases.

Meningitis, diphtheria, tuberculosis, measles, rubella, mumps, and even simple flu, colds and the new forms of flu that have appeared in recent years. In some environments the problem of airborne transmission is particularly critical, especially those places where there is a high density or turnover of people (public places, meeting places, schools, kindergartens etc.), or healthcare or surgical environments. Some healthcare environments are even more critical, for example dental environments, where the sprays and ultrasounds used spread microparticles which are then transported into the environment. All these infections are increasingly widespread, so much so that in some cases they are even defined as pandemics, generating high costs and major social problems. Based on the recommendations of the CDC (Centers of Disease Control and Prevention), devices to treat the environmental bioburden can immediately be applied to reduce the risk of transmission of airborne diseases, and these systems can be used in any enclosed space.

The solution

The solution

TECNO GAZ is the manufacturer of STERILAIR Pro, a device that we first studied, designed and produced for dental use 20 years ago with the aim of creating an extremely high-performance device using UV-C mercury vapour discharge lamps tested for the abatement of volatile biological particles with a life of 9000 hours, simple and intuitive to use, fully programmable and maintenance-free.

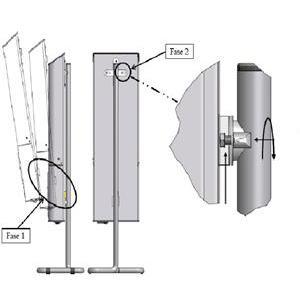

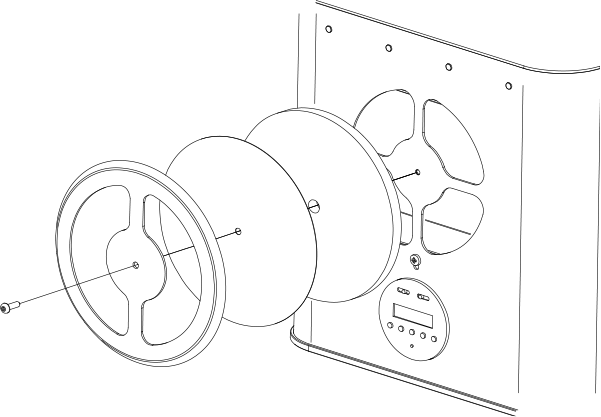

STERILAIR Pro is equipped with 4 lamps (which are the active treatment agent), enclosed in a special reflective chamber and this ensures maximum biological results. We also used a self-cleaning filter (up to 2000 hours) to block dust and microparticles, avoiding the use of other filters that reduce the air flow rate and require periodic maintenance.

Thanks to the choices made we can guarantee optimum results, eliminating periodic costs and ensuring the highest possible safety levels.

Thousands of dental practices and doctors in Italy and around the world use this extraordinary system.

Using STERILAIR Pro means:

- Reducing the risk of operator contamination, as also required by the Consolidated Safety Act and recently also recommended by the WHO (World Health Organisation)

- Reducing or eliminating the potential contamination of operators and patients

- Having a bacteriologically safe environment

Protect your professional reputation by protecting your health and that of your employees and patients. STERILAIR PRO is the first system dedicated exclusively to biological air treatment.

Boasting an innovative design, STERILAIR PRO overcomes the problems of direct and indirect exposure to short wavelength ultraviolet rays (UVC 254 nm) and can be used continuously even in the presence of people, without any risk to the latter.

The most effective means for destroying microorganisms in the air.

|

The device works on the basis of a closed loop forced ventilation system. The air sucked in by STERILAIR Pro first passes through a dust filter located in the intake, which is designed to block the coarsest pollutants, giving the air an initial purification. The air then enters the irradiation chamber in direct contact with the mercury vapour tubes which, thanks to the emission of UV-C radiation, carry out maximum germicidal action. The air is expelled from the outlet nozzle thus carrying out microbiological abatement.

The great advantage of this system is the absolute lack of risk to humans as there is no leakage of UV-C radiation from the equipment and no ozone is produced.

THE BEST ADVANTAGE OF STERILAIR PRO is that it can carry out the continuous and constant disinfection of the air in any environment, during any working phase and in the presence of operators. You can programme STERILAIR Pro to switch on a couple of hours before your arrival at the practice and then keep the equipment on throughout your working day.

STERILAIR Pro

STERILAIR Pro

Dimensions

Primary filter

Sterilair PRO

Sterilair PRO sucks in up to 120m3 of air from the surrounding environment per hour, conveying it towards the 4 Philips UVC lamps which thanks to their germicidal power treat the air before it is re-circulated. We use mercury vapour lamps because of their excellent performance levels and because the radiation emitted is absolutely safe for humans.

Sterilair PRO sucks in up to 120m3 of air from the surrounding environment per hour, conveying it towards the 4 Philips UVC lamps which thanks to their germicidal power treat the air before it is re-circulated. We use mercury vapour lamps because of their excellent performance levels and because the radiation emitted is absolutely safe for humans.Timer

The device is equipped with a programmable weekly timer that allows the air in the practice to be treated even before the arrival of operators and patients. This makes the work area perfectly safe from the start. You can also set the device to power off and avoid unnecessary energy waste (such as at night or at weekends) and increase the duration of the benefits of Sterilair PRO.

With the integrated and programmable timer you might forget you have it, but it won’t forget you!

Controlled ultraviolet radiation

Controlled ultraviolet radiation

There are various methods for decontaminating air, such as free ultraviolet radiation, chemical methods using iodoform, chlorhexidine, or quaternary ammonium derivatives, nebulised using special equipment. These methods, although considered effective, have a temporary effect and can only be used when there are no operators present and in situations of absolute inactivity.

The most suitable and absolutely most effective method is definitely the use of ultraviolet radiation at controlled wavelength. This performs an intense microbicidal and virucidal activity on numerous microorganisms. It acts by blocking the reproductive capacity of microorganisms by altering their chromosomes.

The great advantage of our system is the absolute lack of risk to humans as there is no leakage of UV-C radiation from the device.

Low pressure mercury vapour discharge lamps

Features

- They emit short-wave UV radiation with a peak of 253.7 nm (UV-C) for an effective germicidal action.

- The glass of the lamp acts as a filter to the ozone line (185 nm).

- The protective inner coating keeps the efficacy of the flow of UV-C rays constant over time

- A warning on the lamp indicates the emission of UV-C radiation

- Neutralization of bacteria, viruses and other primitive organisms.

- Enables disinfection of water, air and surfaces in hospitals, pharmaceutical and bacteriological research laboratories and in food processing industry companies such as dairies, breweries and bread factories.

- Disinfection of drinking water, wastewater, swimming pools, air-conditioning systems, cold rooms, packaging materials, etc.

- Use in a multitude of photochemical processes.

Image gallery

Image gallery

Download

Download

Biological Risk_(PL-CZ).pdf

5.98 MB

SterilAirPro (Deutsch)

1.74 MB

SterilAirPro (English)

1.73 MB

SterilAirPro (Español)

0.81 MB

SterilAirPro (Français)

0.66 MB

Sterilair Pro (Italiano)

0.99 MB

INSTRUCTION MANUAL (ITALIANO)

21.84 MB

INSTRUCTION MANUAL (ENGLISH)

21.84 MB

INSTRUCTION MANUAL (FRANCAIS)

21.84 MB

INSTRUCTION MANUAL (DEUTSCH)

21.84 MB

INSTRUCTION MANUAL (ESPANOL)

21.84 MB

INSTRUCTION MANUAL (PORTUGUÊS)

21.84 MB

.jpg)

.jpg)

.png)

.jpg)