To do this you need a research and development department that is able to develop ideas, projects and products. With this logic Tecno-Gaz and Dental Machine have combined their resources to develop an innovative technology project that is able to meet the new needs of the dental market. After more than two years of research and development and the contribution of many professionals, we have created the Quantum line of milling machines, the ultimate expression of digital technology in the dental field. An Italian-made device designed, developed and produced entirely at the Dental Machine/Tecno-Gaz plants.

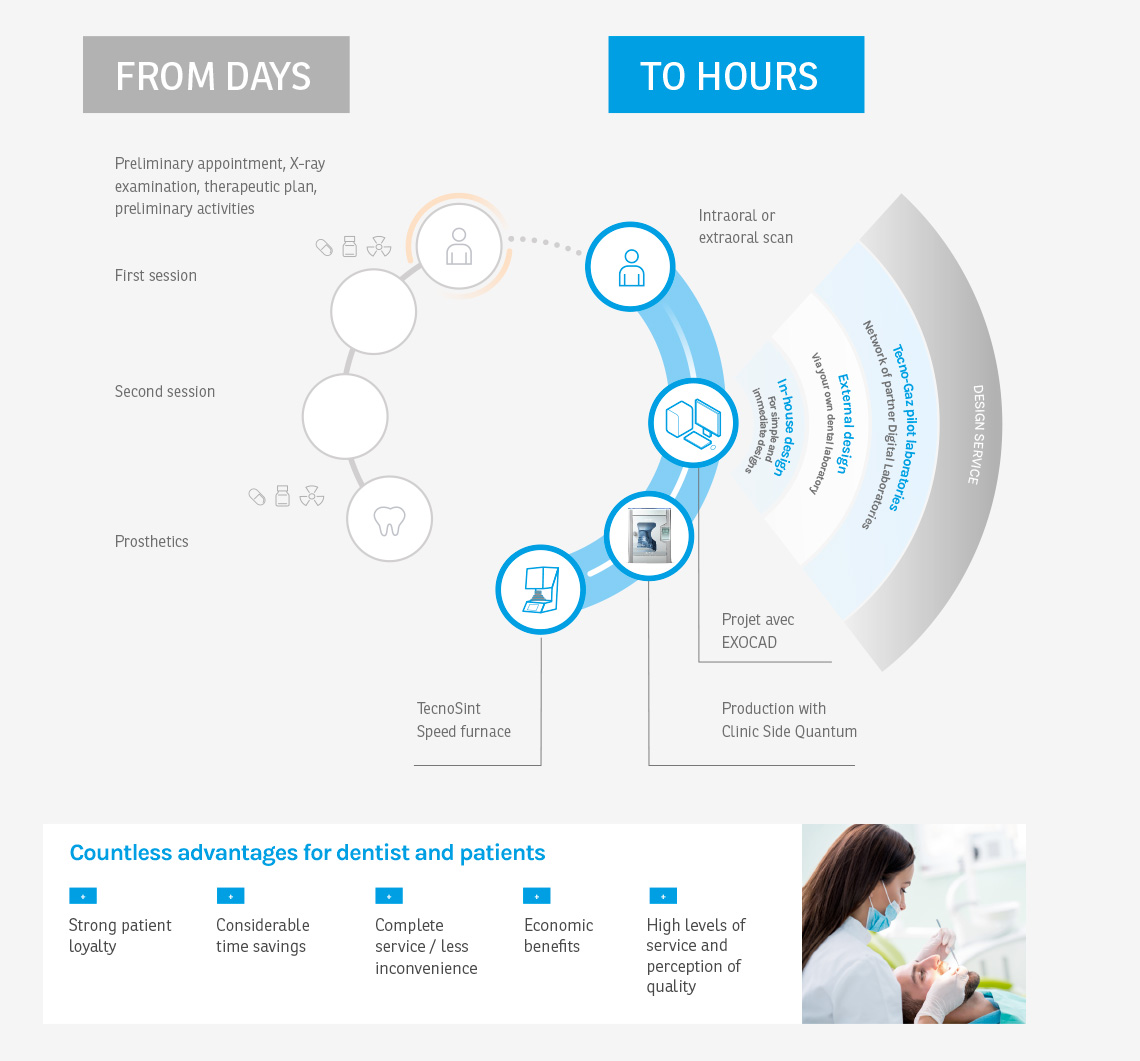

Any advanced dental practice has digital systems that allow it to interact quickly and accurately with its dental laboratory. The use of Quantum represents the completion of this integrated digital process (practice/laboratory) which completes the digital flow and provides the highest level of therapeutic support, in parallel with an extraordinary quality experience for the patient. Quantum was created to be a high-quality tool within the practice and this is why it incorporates unique features specifically designed for the digital development of the dental field.

Quality and speed combined.

Can it be done?Quality and speed must be combined to offer both guaranteed clinical results and the possibility of making implant-prosthetic products at a rate that was previously inconceivable. Quantum is designed to be fast and extremely accurate.

But it also needs to be easy to use!

If you can use your smartphone you can use Quantum! Anyone can learn how to use it in a very short time and without any specific training.

...and easy to manage!

Dental practices are medical facilities where the focus must be on the patient. That’s why we have designed Quantum with solutions that minimize the need for maintenance.

Next generation brushless motors ensure speed, quality and repeatability.

The first milling system that is easy to integrate in the practice and immediately operational as it is easy for everyone to use.

Various expedients increase productivity and service life with minimum maintenance.

Download product brochure.

Quantum was created to offer extraordinary levels of reliability and quality. The result of specific experience in the world of high quality milling, Quantum embodies unique user-friendly, intuitive features, essential in the delicate workflow of a modern dental clinic. Quantum is the ideal platform for building a solid, digital workflow, crucial for opening up new opportunities and new markets.

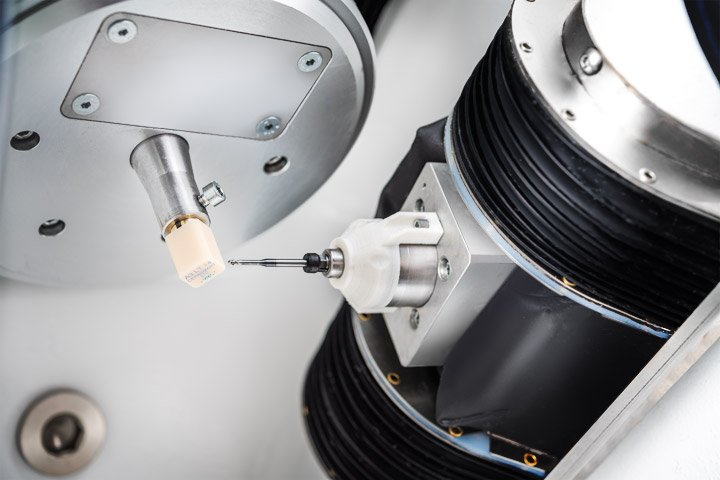

The load-bearing structure of the entire system is an aluminium monobloc made in a single casting, which guarantees extreme rigidity, the interconnection of all elements and maximum precision of movement to ensure longer tool life and reduced production times.

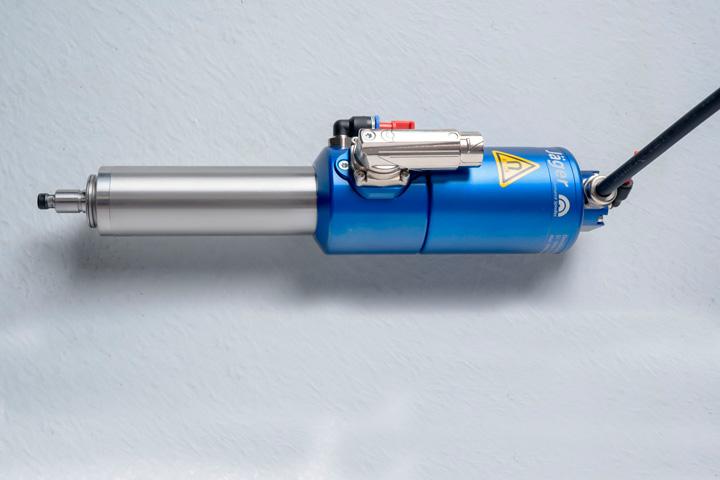

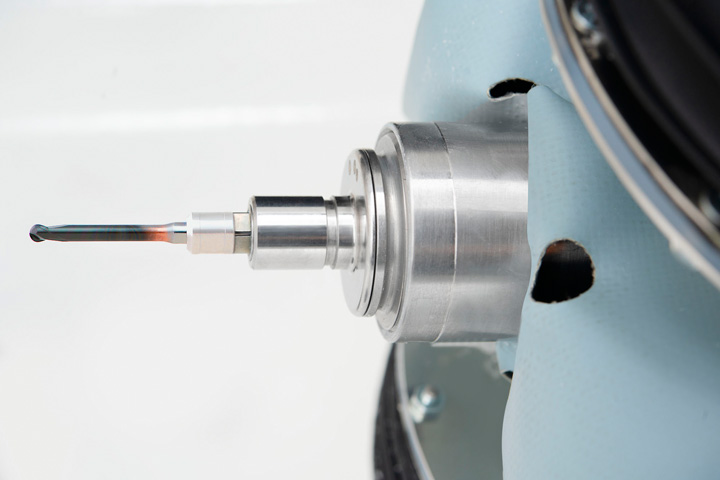

Quantum makes use of spindles made by Jäger, a market-leading German manufacturer: a guarantee of quality, performance and durability for optimal milling at both low rpm and high speeds. The deciding factor is the torque of this electro-spindle (8Ncm). This makes Quantum powerful even at 20,000 rpm. This sets it part from other electrospindles that must operate at very high speeds, which are not always necessary (or appropriate in some cases). High rotation speeds can also burn the tool and significantly compromise its service life.

with encoder for the maximum surface quality of the prosthesis.

with automatic changeover depending on the material.

up to 65mm in length.

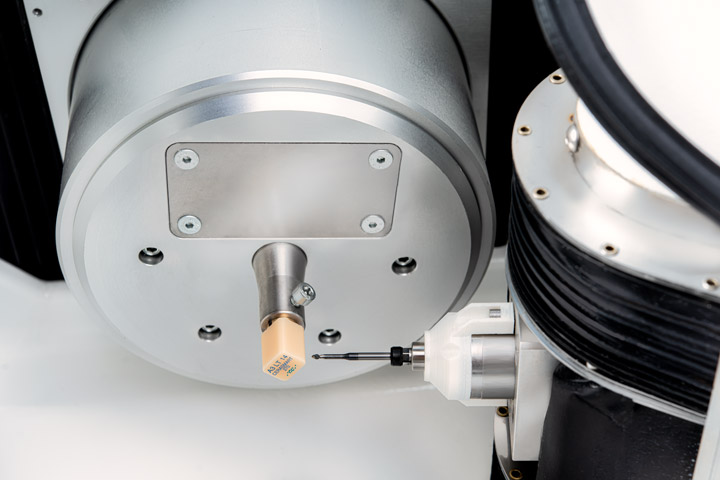

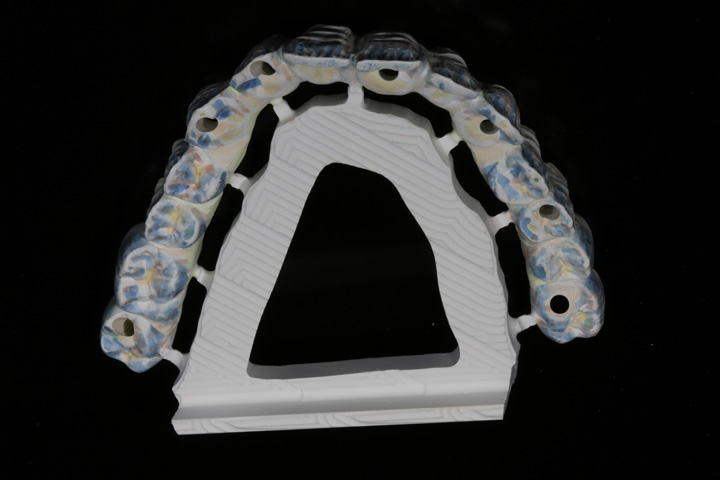

Thanks to the 5-axis inclination the tool can reach all areas of the tooth, even the undercuts, for a perfect reproduction of the tooth morphology.

With Quantum, enter the world of digital dentistry with all the quality and reliability necessary to ensure a high return on investment.

Simple, clear and guided workflow.

N.B. (We mean speed in the treatment of the patient and speed also in the learning curve).

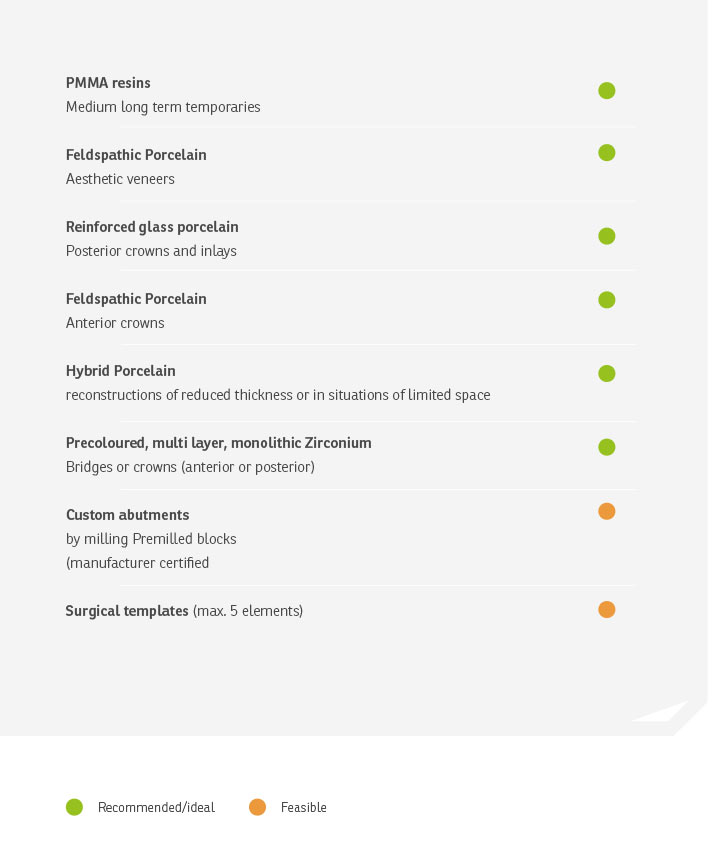

In the dental CAD/CAM sector a pre-milled refers to a titanium or chromium-cobalt block with a pre-machined engagement, from which a personalised abutment is obtained by milling. It allows you to combine industrial precision engagement with the versatility of digital dental technology when realizing the shape of the abutment.

The Pre-milled material makes it possible to produce a personalised abutment with certified connection in less than 20 minutes.

| Number of Axes | 5 continuous |

| Dimensions - mm - WxHxD | 580 x 710 x 610 |

| Weight | 150 Kg |

| Tool Change | Automatic |

| Number of tool positions | 11 |

| Electrospindle | Jäger 0,55 kW - 60,000 rpm |

| Spindle torque | 8 Ncm |

| Axis anglee | A+- 15° |

| Tool shaft diameter | 3 mm |

| Tool breakage detection | Automatic |

| Power supply (single-phase) | 230 ± 10% V - 50÷60 Hz |

| Compressed Air | Always integrated |

| Linear axis resolution | ± 0.003 mm (3μ) |

| Duplicated tool management | Optional |

| Dry processing | Yes |

| Wet processing | Yes |

info@tecnogaz.com

+39 0521 8380

Strada Cavalli, 4 - Sala Baganza - Parma - Italia