Towards the dental laboratory 4.0

Digital technology breaks new ground and brings new possibilities, which can be exploited only if the dental technician is able to play his new role.

The dental laboratory sector, which has always been associated with manual ability and skills of the single technicians, is undergoing a total change in recent years, thanks to the new digital technologies. Digitalisation, virtualisation and CAD/CAM systems are the new instruments, and the new language of the dental technician. At the start of this fourth industrial revolution, great opportunities can be seized for those who can perceive and manage the change.

The opportunities offered by digital technologies

Technology neither creates, nor destroys professionalism. It adds value to it.

First of all, it is important to understand that the digital age adds great value to the role of the dental technician, who is not a mere user of preset systems, but an autonomous operator specialised in the use of digital tools.

Strenghts

- Speed

- Repeatability

- Wider offer

- Possibility to increase the production volumes more easily than in the past

Weaknesses

- Medium investment

- Learning curve

Opportunities

- Anticipate the competitors

- Recover centrality in the production cycle

- Provide online services

- Increase profitability

Risks

- Present only if technological solutions not properly supported by the supplier are chosen

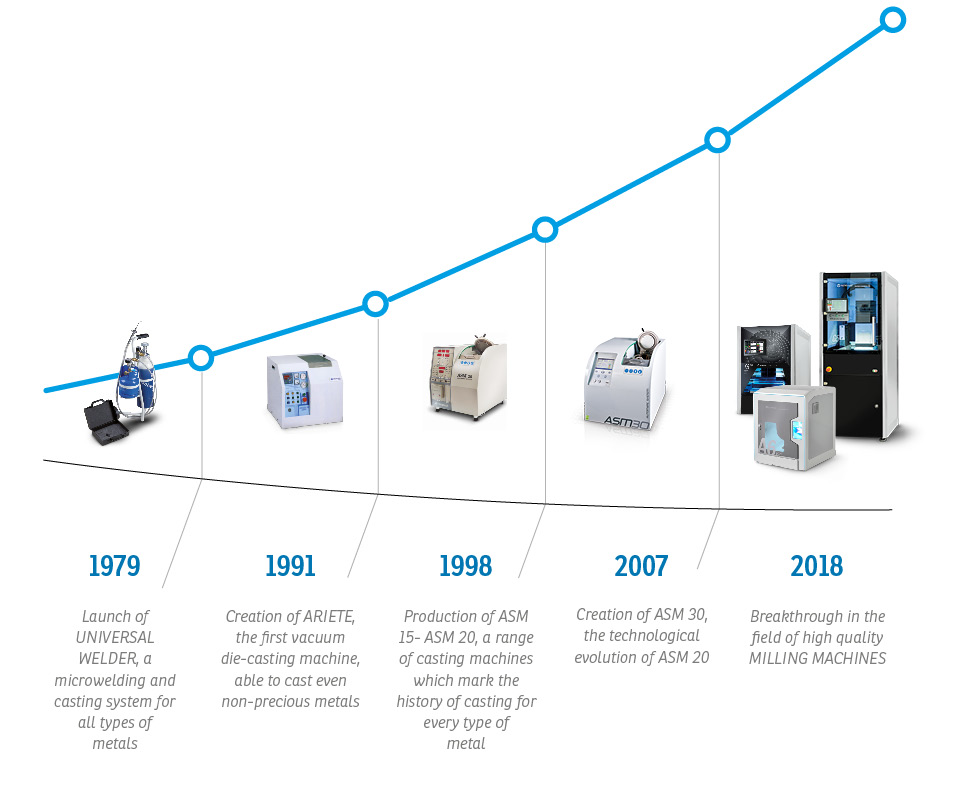

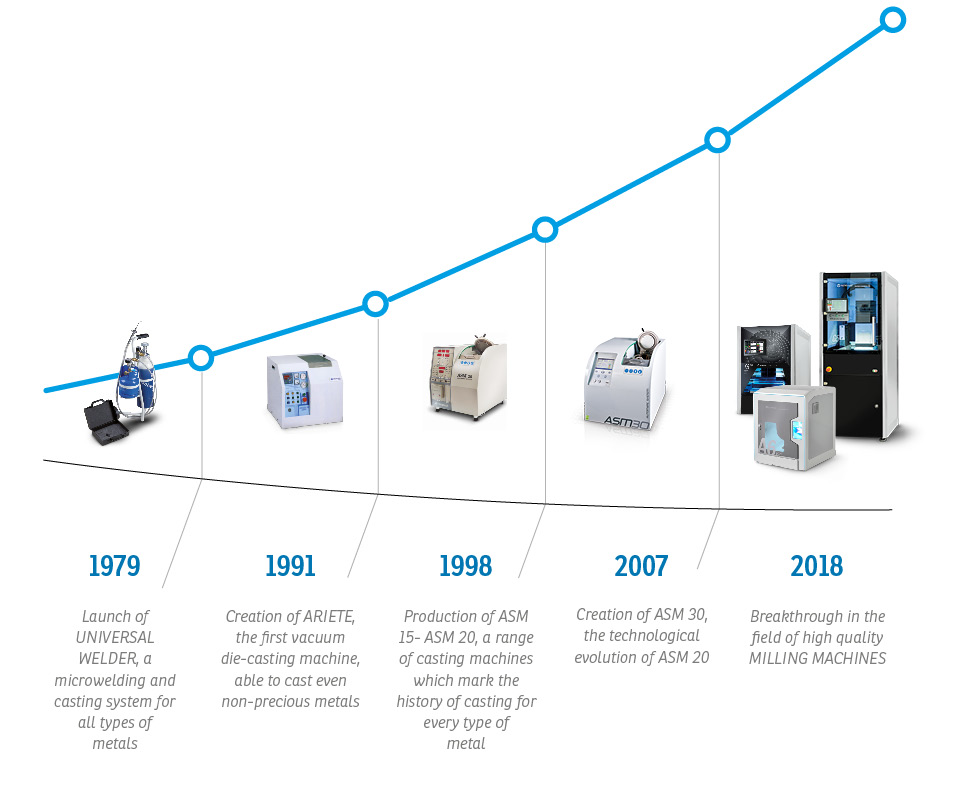

Tecno-Gaz and the dental laboratory 4.0 evolution

We have been developing technologies and methods for about

40 years, thus becoming leading figures in prosthetic dentistry. This industrial commitment will take us as leaders into the world of milling and CAD/CAM systems.

Academy. The route that we want to follow with our customers

In Tecno-Gaz, first we want to be consultants, and then partners; therefore, we have organised a project named Academy. A consultancy course which we guarantee to our customers as a sign of the cooperation culture which we are implementing in this project. Academy involves a specific programme articulated in 4 main points.

- Pre-sales information activities

The purchase of a milling machine requires an organisational review of the working approach; therefore it is very important to know all the aspects involved in this new project. Tecno-Gaz arranges specific meetings held by specialists, who will be able to give complete information to potential customers, in order to let them know all the aspects connected with the digital workflow process. This activity will also be personalised according to the needs of every single potential customer, who will have the chance to receive information and proposals tailored to his/her needs.

- Shipment – installation – training

The shipment and delivery of any Tecno-Gaz Axya product are very important. The milling machine is delivered by qualified personnel who carry out the correct installation and commissioning of the device. A theoretical/practical training is subsequently arranged, with initial tutoring in the practical use of the device.

- Post-sales services

• Technical support and tutoring with the possibility to access multilevel services.

• Possibility to request 2nd level training.

• Possibility to benefit from supplementary services in case of machine downtime.

- Personalised financial and commercial proposals

Every sales proposal is tailored to the customer’s needs.

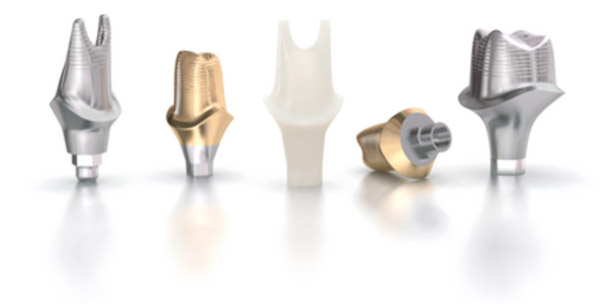

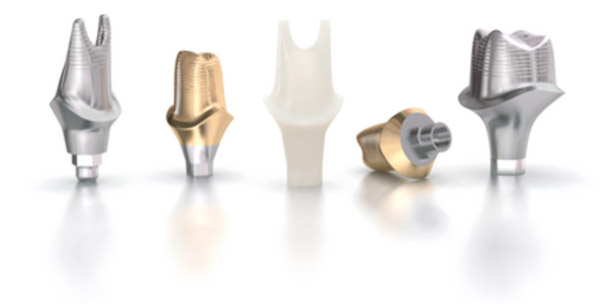

Materials and prosthetic works

All-ceramic and lithium silicate materials

Crowns and fixed veneers on stumps and implants, bridges up to 3 units, onlays, personalised abutments

Hybrid ceramics

Hybrid ceramics: fixed crowns on stumps and implants (NO LAVA), inlays and onlays

Composites

Inlays and onlays

PMMA

Temporary crowns on stumps and implants, temporary bridges

Zirconia

Fixed crowns on stumps and implants, bridges, personalised abutments

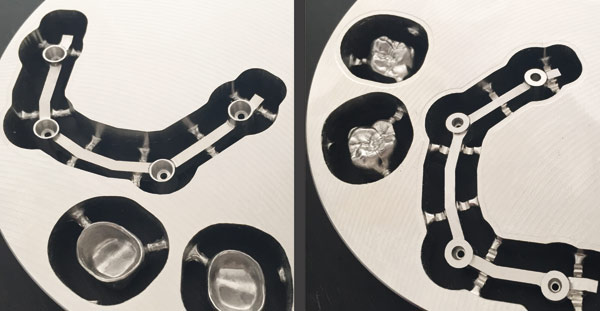

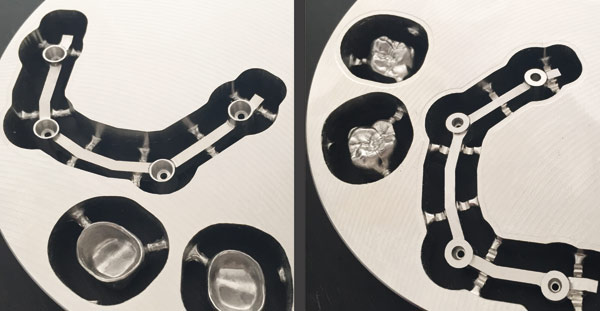

Metals

Fixed crowns on stumps and implants, bridges on stumps and implants, personalised abutments, bars and Toronto bridges

The range.

The range of

Tecno-Gaz milling machines has been designed to meet all the requirements, ranging from in-house production in dental surgeries and clinics to dental laboratories of all sizes. Every model has been designed to become an essential element of the digital flow and to add the maximum value to time, profitability and professionalism.

- A6 - Entry level high performance machine usable with all pre-sintered metals + soft materials and silicates, wax, PMMA, PEEK, resins, ceramics and lithium disilicate

- C5 - Medium Level usable with all pre-sintered metals + soft materials and silicates, thermoplastic materials, wax, PMMA, PEEK, resins, zirconium dioxide and aluminium oxide

- C5PLUS/C5EVO - Medium Level usable with Wax, PMMA, different resins, composite, pre-sintered zirconium dioxide and aluminium oxide, hydroxyapatite, titanium (grades 2 and 5), Cr-Co

- G5 - Top level: it can mill any kind of prosthetic work from any kind of material. Linear optical lines on the X, Y, Z axes, Granite frame