No need to buy new instruments in order to make up for instrument unavailability due to long treatment times (as with all the other devices).

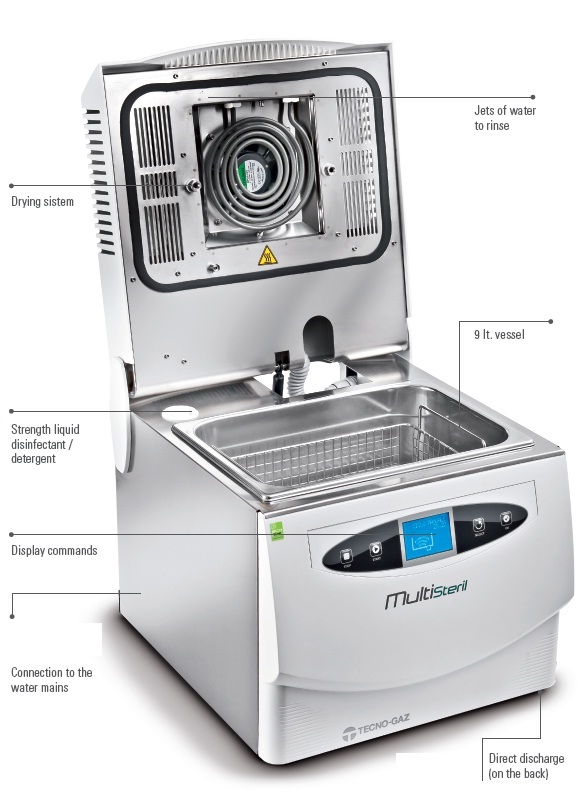

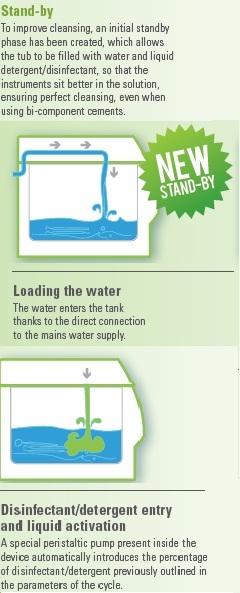

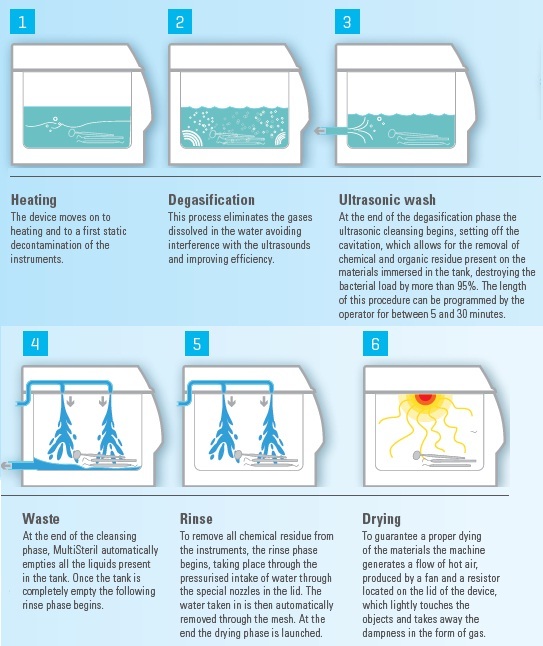

All the disinfection, cleansing, rinsing and drying steps are performed automatically, without human intervention; this permits to follow the protocols correctly and to avoid negligence or operative mistakes.

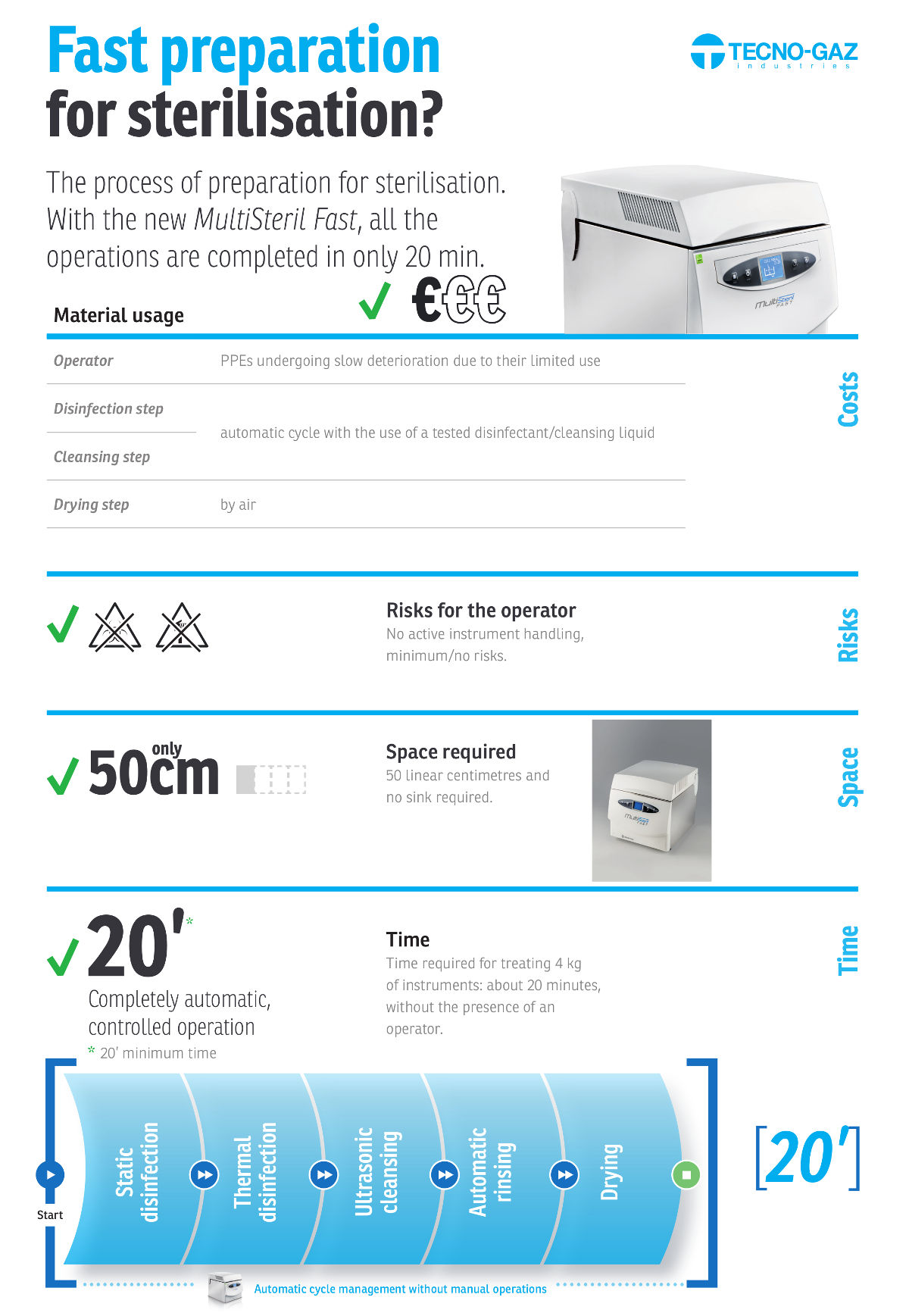

Since neither handing, nor transfer of infected instruments and materials are involved, there are no risks of accidents at work, because all the procedures are automatically managed by MultiSteril Fast according to preset sequences which do not involve the operator in any way.

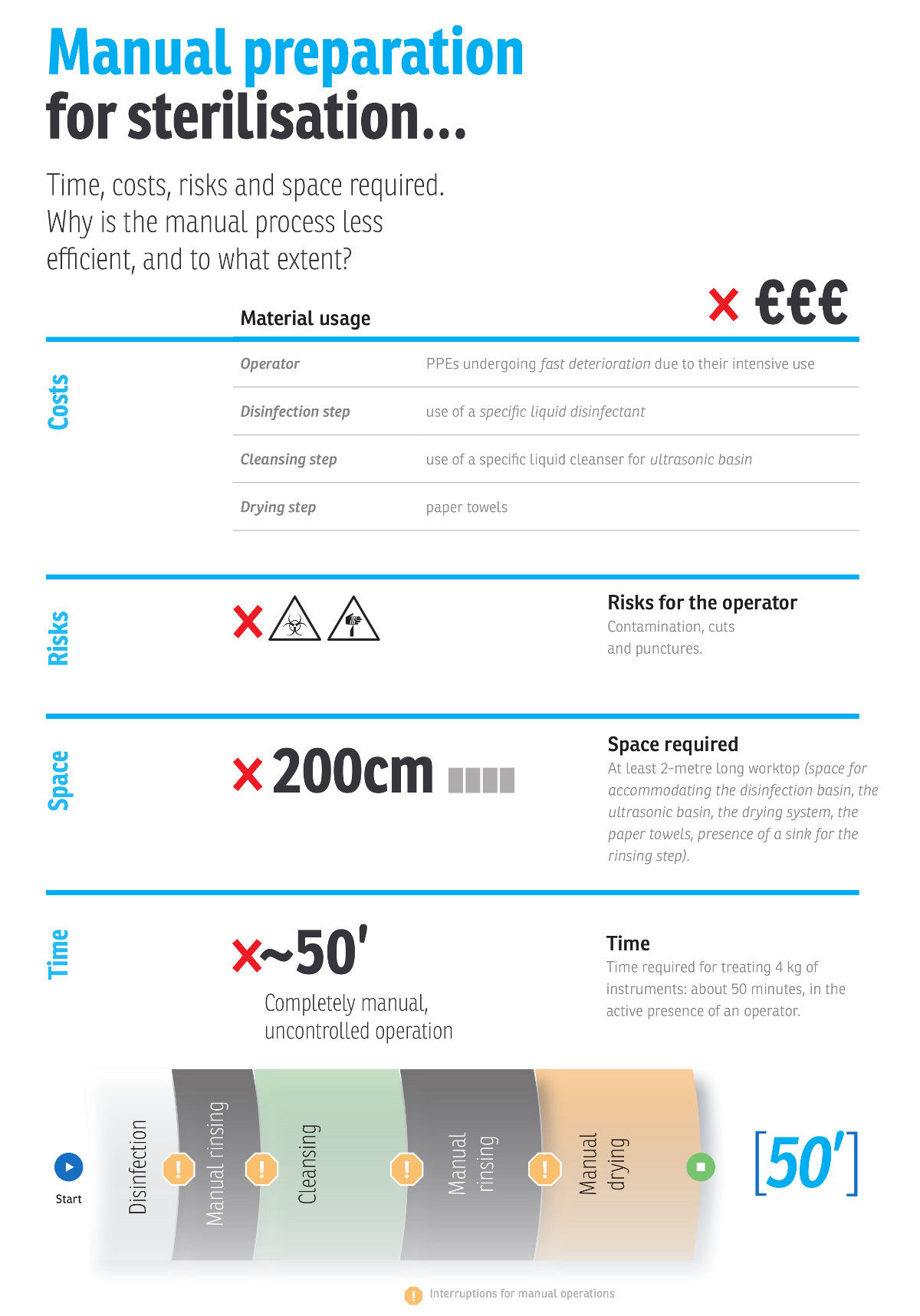

Today, all the steps of the sterilisation cycle are carried out manually by the operator, who spends a great deal of time in performing all the protocols. MultiSteril Fast does not require operator intervention; every step is automatic and cycle times are halved.

The whole process does not require the continuous presence of an operator, the management of the liquids used is automatic and there is no need to carry out cleaning and disinfection at the end of the cycle, with a great reduction of total time and costs.

You can be totally sure that the protocol is followed in an absolutely correct way, with a repeatable, consistent quality.

Assistants spend a lot of time in the preparation phase for instrument sterilisation, because of multiple and complex manual procedures. Multisteril is completely automatic.

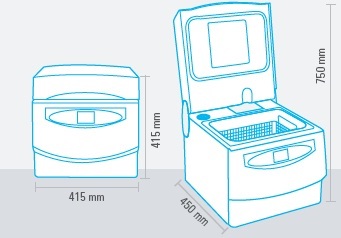

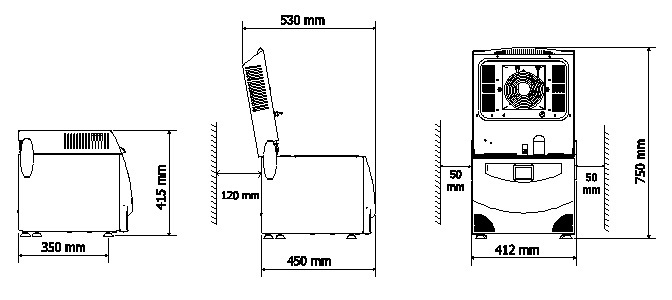

Space is another important problem. In fact, sterilisation rooms are often small; so, space rationalisation is very valuable. Multisteril does everything in a 40 cm space.