Art. 2900S

Device for shoe coating ORMA

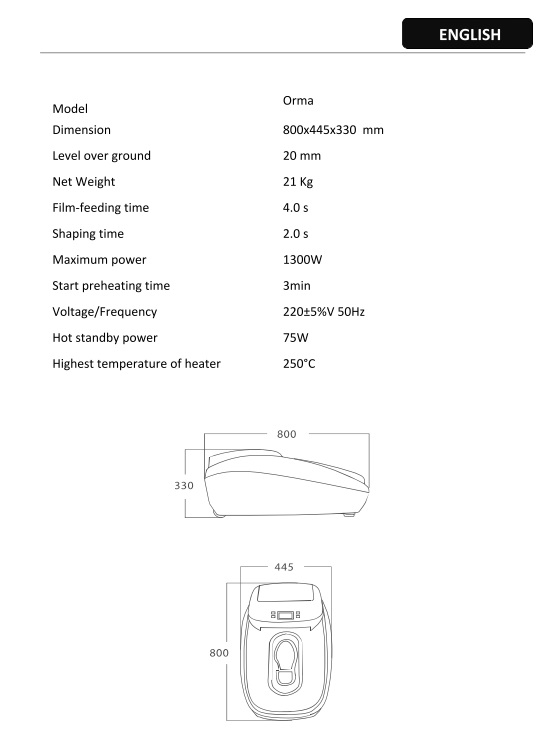

Orma

Device for shoe coating Mod. ORMA

Surgical protocols require the adoption of PPE (Personal Protective Equipment) by operators and patients. Shoe coating must isolate the shoes, which can obviously “carry” infectious materials.

Under normal ambulatory medical activities, in which the fully clothed patient undergoes surgery or invasive therapies, he/she must be protected with shoe coating.

The normal manual operation of putting on shoes can, for certain categories of people, cause discomfort and/or require a tedious physical effort.

Advantages

With ORMA, it is not necessary to insert special shoes into the device, because a roll of heat-shrinkable film is used.

It is not necessary to buy shoe covers, and this generates time saving, avoids large quantity of waste disposal, eliminates the need for different sizes of shoe covers, and results in a significant cost saving.

ORMA automatically “builds” the shoe coating by placing the shoe in the specific compartment of the device, where a thermoplastic film, under the activation of the heating system creates a shoe coating in real time, following the shape of the shoe.

The coating fits perfectly, creating a total insulating barrier. It is also waterproof and does not prevent or impede movement. The plastic coating lasts longer than simil-fabric coatings.

Great attention to hygiene

The use of shoe coating as a standard procedure for staff and patients is synonymous with hygiene and prevention. All this creates a positive impression in patients and reduces the microbial distribution in surgical and working environments.

Orma facilitates the management of this process, reduces risks and costs, so projecting a favourable image of the whole clinic. It is an elegant device, whose technology is controlled by a microprocessor card, with programmable controls.

The whole process of film wrapping and shoe coating is done by inserting the shoe in the footprint of the device. A specific support (Art. 2910S) has been designed (as optional available upon request) to maintain balance in the preparation stages and in the final shoe coating removal.